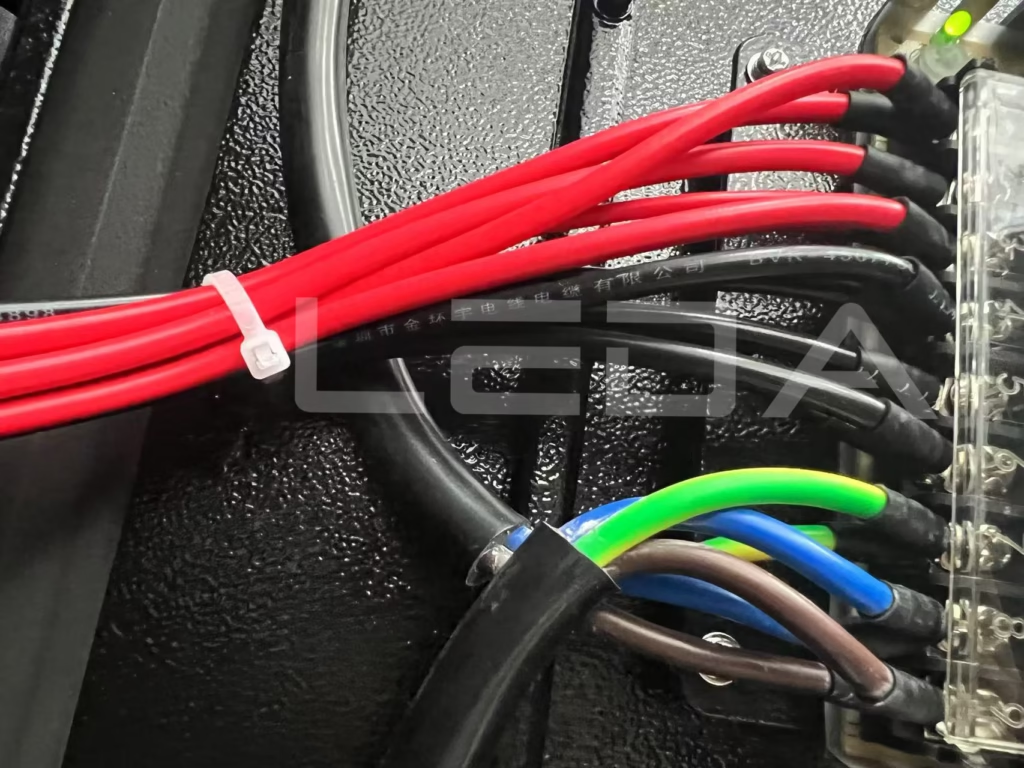

Wires for LED Display Screens

In the world of LED display screens, the choice of wiring plays a crucial role in ensuring performance, safety, and durability. Whether you’re powering an LED display board, a stable LED display screen, or an intricate LED video wall, selecting the right wires is essential for optimal functionality. Here, we’ll explore common wire types, their classifications, the impact of external conditions, and the risks of using substandard wiring.

1. Common Wires Used in LED Display Screens

Different parts of an LED display screen require specific wire types to ensure safe and efficient operation. Below are the typical wires and their current-carrying capacities:

1.1 Wires for the Control System

- Specification: 0.5 square millimeters

- Current Range: 2-5 amps, depending on ambient temperature and cable length.

1.2 Wires for LED Modules

- Specification: 2.5 square millimeters

- Current Range: 16-25 amps, providing steady power to LED modules for consistent brightness and operation.

1.3 Wires for LED Cabinet Power Supply

- Specification: 2.5 square millimeters

- Current Range: 16-25 amps, similar to module power wires, but these handle higher load concentrations.

2. Wire Classifications and Performance

The two primary types of wires used in LED display boards are pure copper wires and copper-clad aluminum wires. Each has unique characteristics:

2.1 Pure Copper Wires

- Advantages: Superior conductivity, higher current capacity, minimal heat generation, strong mechanical durability, and excellent corrosion resistance.

- Best Use: High-performance LED video walls or any installation prioritizing long-term stability.

- Drawback: Higher cost.

2.2 Copper-Clad Aluminum Wires

- Advantages: Lightweight and cost-effective due to an aluminum core coated with copper.

- Drawbacks: Lower current capacity, higher heat generation, and faster aging compared to pure copper.

- Best Use: Low-budget, temporary setups.

At the same current load, copper-clad aluminum wires generate significantly more heat than pure copper wires, increasing the risk of overheating and compromising the security of LED display screens.

3. Environmental Factors Affecting Wire Performance

The working conditions of an LED display screen are often impacted by environmental factors. Key considerations include:

- Temperature: High ambient temperatures reduce a wire’s current-carrying capacity. A 10°C increase can lower a cable’s capacity by 5%-10%.

- Humidity: Excessive moisture can degrade insulation, increasing the risk of short circuits and reducing wire longevity.

- Installation: Excessive wire length or sharp bends can cause resistance buildup, leading to voltage drops and reduced efficiency.

4. Risks of Using Substandard Wires

In an effort to cut costs, some manufacturers use non-standard wires in their LED display boards and video walls. However, this practice poses serious risks:

4.1 Fire Hazards

Low-quality wires lack adequate current capacity, leading to overheating and potential combustion, jeopardizing the security of LED display screens.

4.2 Performance Instability

Poor-quality wires can cause inconsistent power delivery, resulting in LED display screen brightness fluctuations, LED display module malfunctions, or complete LED display system failure.

4.3 Shortened LED Display Board Lifespan

Substandard wires degrade quickly, causing connection failures and reducing the lifespan of the entire LED video wall or display.

4.4 Higher Maintenance Costs

Frequent repairs due to faulty wiring increase maintenance expenses and hurt customer satisfaction and brand reputation.

5. LEDA Commitment to Safety and Quality

At LEDA DISPLAY, we prioritize the safety and stability of every LED display screen we produce. We strictly use industry-standard wires to ensure optimal performance and long-term reliability. By putting quality and security first, we deliver solutions that not only meet but exceed customer expectations.

Whether you’re installing an LED display board in a retail environment or building a dynamic LED video wall, you can trust our commitment to excellence. Choose quality, choose safety, and choose stability—choose LEDA DISPLAY.

Latest Articles

- LEDA LED Displays Gained Recognition from Senior Brazilian Engineers, Successfully Applied in Local Highway Projects

- LEDA VMS Display: Illuminating the Future of Traffic Management

- P10 Traffic LED Display

- LEDA P10 P16 P20 Outdoor Traffic Display Board Rear Service

- Unveiling the Ideal Highway LED Display Supplier: Your Comprehensive Guide