RGB SMD LED Video Wall Moisture-proof User Instructions

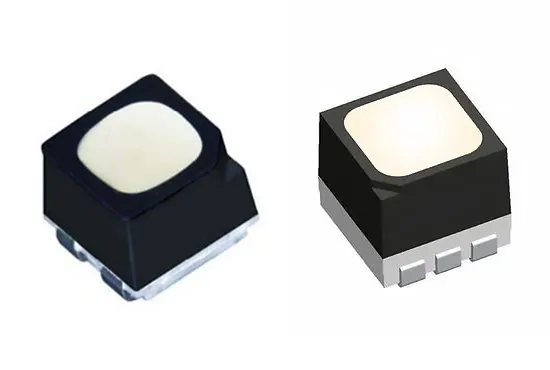

LED lamp beads is the most important components of the led display screen. Preventing moisture from affecting the LED lamp beads is very important for the performance and longevity of the LED video wall.

LED lamp beads belong to humidity susceptibility component (indoor and outdoor product). When you receive the display screen, there are several key points you must pay attention to.

1. Regular maintenance for LED video wall

1.1 The way to remove moisture and dry the display Screen

The LED display screen should be used regularly. When the LED video wall operates, the heat from the LED chips prevents moisture buildup. If the led display remains off for an extended period (usually 5–10 days, depending on the environment and climate), dehumidification is necessary before turning the led display board back on.

Accordingly, the recommended method of dehumidification is heating up gradually. We can edit a simple program to bring up brightness from low to normal. The steps as below for your reference.

- →(0~2nd)h energize but with LED video wall brightness at 0

- →(2nd~4th)h turn up LED video wall to brightness level 10

- →(4th~6th)h turn up LED video wall to brightness level 20

- →(6th~8th)h turn up LED video wall to brightness level 30

- →(8th~10th)h turn up LED video wall to brightness level 40

- →(10th~12th)h turn up LED video wall to brightness level 50

- →(12th~14th)h turn up LED video wall to brightness level 70

- →(14th~16th)h turn up LED video wall to brightness level 90

- →(16th~18th)h turn up LED video wall to brightness level 120

- →(18th~20th)h turn up LED video wall to brightness level 150

- → (20th~22nd) (h) turn up LED video wall to brightness level 200

Note: The operation time can be extended or shortened based on the application environment, climate, and duration of screen inactivity.

Due to varying levels of humidity in LED display boards, this method may not guarantee complete dehumidification. Therefore, we recommend that customers turn on the LED video wall daily, if possible, to assist with dehumidification.

Additionally, customers should configure a program in the LED display control system to log the operation status of the LED display (serving as an operation diary). This log should include details such as usage time, turn-off time, warm-up duration, indoor temperature, and humidity levels for traceability.

1.2 Case Study

Customer A uses LED studio software for automatic regular startup to reheat and dehumidify the LED video wall. This is achieved by setting up the master control computer and integrating LED hardware, including a light sensor.

If the LED video wall is off for 5 days (or 10 days in dry areas), the LED control software activates automatically. It gradually increases the gray scale level for slow preheating. This process removes moisture and prevents LED lamp bead failures caused by humidity. The preheating cycle lasts for 22 hours.

1.3 How to cope with the humid season.

During rainy and humid seasons (such as around the Spring Festival in China), moisture-proof measures are essential. Run the LED video wall regularly and avoid leaving it powered off for more than 5 days.

If a fixed LED display has been off for over half a month and covered with a curtain, dehumidification is crucial. Preheat slowly using the recommended method to remove moisture. After preheating, play videos on the display for 1–2 days. Adjust this duration based on recent weather conditions.

2. During the installation of the LED display screen, take care to prevent moisture.

2.1 Selection of LED display screen installation time

Please avoid installing the LED video wall when the building is still under renovation, and the led video wall must be installed after the

building renovation is completed, because renovation environments often have high humidity and acidity, increasing the risk of LED lamp bead failure.

If simultaneous installation and renovation are unavoidable, wrap the LED display screen with curtains and run it for at least 2 hours daily, playing videos to remove surface moisture.

2.1.1 Case Study

In March 2017, Customer B used the indoor LED SMD lamp beads from the 2020 series, which experienced issues with the LED lamp beads, including serial lighting failures and dead LEDs.

The LED wall video was installed on the first floor of a building under renovation near the sea. The interior finishing and LED video wall installation occurred at the same time. The screen remained powered off for an extended period. When turned on again, it showed widespread issues, including dead LED lamp beads and serial lighting failures. The moisture-damaged LED lamp beads were irreparable, leading to the complete scrapping of the screen. Proper dehumidification and regular operation are crucial for preventing such failures.

Case analysis: The display screen is installed near the sea, where humidity levels are high. The renovation process further increased the humidity. Improper moisture control during this period led to severe humidification of the LED lamp beads. As a result, many LED SMD lamp beads became damaged and non-functional.

2.2 Installation location and preventing moisture damage to the display screen.

- The screen must NOT be directly blown by air conditioner at the front.

If the LED video wall is used in environments like swimming pools, amusement parks, or areas with water exposure, special protection is required. For example, waterproof glass can be used to isolate the screen and prevent water damage. This protection ensures the longevity and functionality of the LED display in humid or wet conditions.

3. Prevent moisture damage in rental LED displays.

3.1 Proper storage of rental LED displays.

- If a rented LED screen gets wet in the rain, it must be cleaned and dehumidified after the event. Make sure to remove any foreign matter and rain from the LED rental board. Then, store it in the flight case. Proper cleaning and dehumidification ensure the screen’s longevity and performance.

- In the flight case, pls put some desiccant

- Before the next event, take out the LED rental screen in advance. Gradually increase the gray scale level, step by step, as outlined in the application requirements. This method helps with dehumidification through gradual lighting.

- Avoid direct storage the rental led wall without processing after event.

3.2 Case Study

In 2021, a rental display screen from a Hong Kong client encountered rainfall during a even. After the event, the workers dismantled the rental display screen, then directly put the cabinet into the flight case. After more than ten days, when using this batch of LED rental board again, the led lamp beads had become damp and oxidized

4. Special reminder

In environment of LED storage, production and using, strong oxidizing disinfectant are prohibited.

Halogenated disinfectants, such as 84 disinfectant, bleaching powder, chlorine-based disinfectants, and chlorine effervescent tablets, as well as peroxide disinfectants like chlorine dioxide, hydrogen peroxide, and peracetic acid, have strong oxidizing properties. These disinfectants can cause corrosion to LED display screens and LED lamp beads.

Note: The case in this document is provided by NATIONSTAR.

Latest Articles

- LEDA LED Displays Gained Recognition from Senior Brazilian Engineers, Successfully Applied in Local Highway Projects

- LEDA VMS Display: Illuminating the Future of Traffic Management

- P10 Traffic LED Display

- LEDA P10 P16 P20 Outdoor Traffic Display Board Rear Service

- Unveiling the Ideal Highway LED Display Supplier: Your Comprehensive Guide